As electronics manufacturing becomes more data-driven and precision-focused, rework systems are evolving to meet the standards of Industry 4.0. A critical area of transformation is BGA (Ball Grid Array) rework, where traditional hot air methods are being replaced by infrared (IR) rework stations that offer better control, efficiency, and traceability.

At the heart of this shift is the ability to reduce thermal stress on components and boards—ensuring higher reliability, lower scrap rates, and smarter repair workflows that align with digital factory goals.

Why Infrared BGA Rework Fits the Industry 4.0 Model

- Non-contact heating for consistent, repeatable rework processes

- Real-time thermal profiling and process data logging

- Reduced component and board damage during repair

- Support for RoHS and lead-free standards

- Improved yield and sustainability in high-mix SMT environments

These systems directly support smart manufacturing principles by enabling tighter process control and deeper analytics at the rework stage.

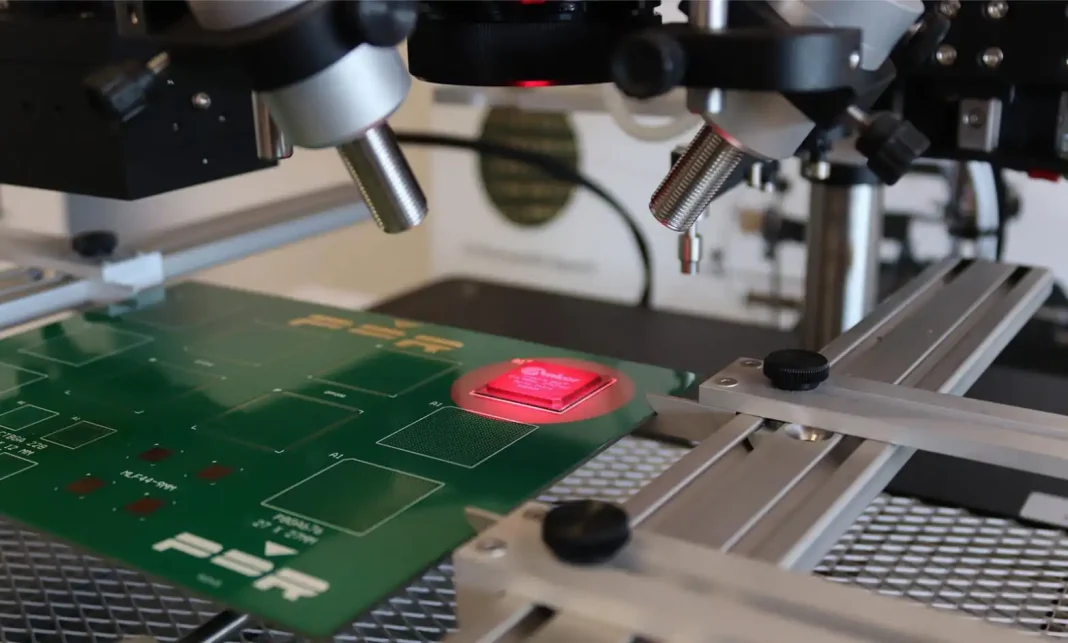

Automated Rework with PDR’s Infrared Platform

Through Etek Europe, manufacturers can access the full line of PDR infrared BGA rework systems, built to serve everything from prototyping labs to fully automated production lines:

- IR-E1 – Compact entry-level rework with thermal control

- IR-E3 – Mid-range system with advanced profile programming

- IR-E6 – High-volume production model for large-format PCBs

- IR-Q3 – Semi-automated rework platform for traceable, hands-free operation

Each model offers thermal feedback control, programmable profiles, and data capture—enabling smarter decisions and process validation, even at the repair level.

Reducing Scrap and Increasing Throughput

When rework can be done without damaging nearby components or internal PCB layers, manufacturers benefit from:

- Fewer process failures and rejected boards

- Faster rework cycles with lower operator dependence

- Reduced waste and better compliance with environmental goals

- Improved overall equipment effectiveness (OEE)

Sustainability Through Smarter Rework

With growing pressure on electronics manufacturers to improve sustainability, rework must evolve from a reactive necessity to a proactive, strategic function. Reusing high-value boards and components—when done with controlled infrared reflow—directly contributes to:

- Lower carbon output per unit

- Reduced landfill impact

- Better materials utilisation

In this context, infrared BGA rework stations are not just tools—they’re enablers of smarter, cleaner electronics manufacturing.

Learn More

For more information on integrating infrared BGA rework systems into your smart factory or production workflow, visit:

https://www.etek-europe.com/divisions/production-equipment/pdr-rework/bga-rework-stations/