Trelleborg Sealing Solutions exhibits advanced solutions for semiconductor applications at SEMICON West in Phoenix, Arizona, October 7 to 9, 2025, at booth 2077.

Kevin Kaufenberg, Business Development Specialist, says: “As trends such as AI, miniaturization, machine learning and high-performance computing demand innovation from semiconductor manufacturers, accelerating time to market while reducing total cost of ownership is critical. At SEMICON West we are featuring the latest additions to our semiconductor portfolio specifically engineered to address the challenges original equipment manufacturers and end users face in this space.”

On display is Trelleborg’s extensive Isolast® PureFab® range which provides excellent performance in aggressive front-end processes including deposition, etch, ash/strip, plasma cleaning and thermal processing such as atomic layer deposition. Comprising leading-edge perfluorocarbon rubbers (FFKMs), the PureFab® range offers unique properties including high-temperature stability, high purity, exceptionally low-trace-metal content and outstanding plasma resistance. This results in reduced particle generation and ultra-low outgassing performance in high vacuum conditions.

Also featured is Trelleborg’s Airseal range of inflatable tubular elastomer seals made from high-grade ethylene propylene diene monomer (EPDM) and silicone rubber materials for load locks and access doors in advanced vertical thermal processors. The seals resist both vacuum and positive pressure, replacing traditional flat gaskets and O-Rings.

Murat Gulcur, Technical Director Semiconductor, says: “Airseals represent a technically improved alternative to standard contact pressure seals and can be easily adapted to match mating surfaces. They simplify the hardware necessary to achieve a seal in a vacuum and speed the process of loading a wafer into the dock and making critical measurements of its surface and circuitry.”

Additionally, Trelleborg showcases chemical mechanical planarization (CMP) parts including liquid silicone rubber (LSR) and high-consistency rubber (HCR) rolling diaphragms used to stabilize the grinding pad and wafer during CMP polishing.

Chris Busby, Global Segment Director Semiconductor, says: “CMP polishing is a critical step in the semiconductor manufacturing process. Our high-quality diaphragms used for air pressure control and damping help mitigate vibration and ensure the process remains future-proof.”

Other products on display critical to sealing in chip manufacturing are bonded slit valve and rocker valve door seals comprised of dynamic rubber-to-metal bonded seals for wafer transfer chambers. These valve seals demonstrate high wear resistance coupled with ultra-low outgassing qualities when bonded to the metal door and are suited for high-volume manufacturing.

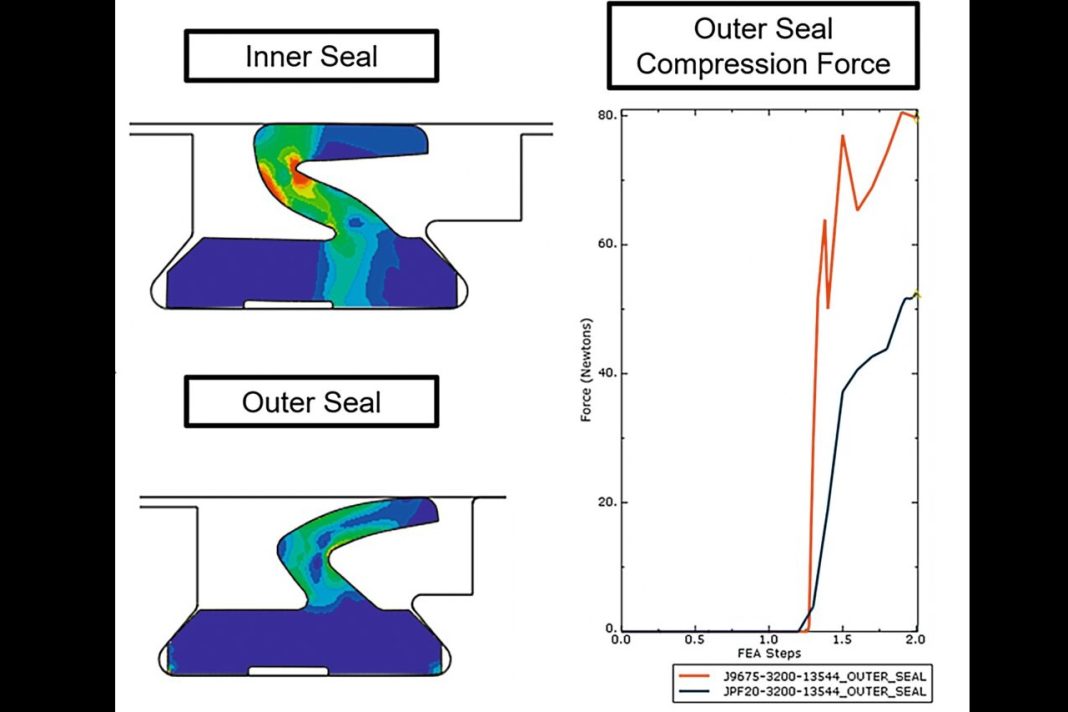

Trelleborg also demonstrates its extensive and rigorous engineering capabilities, including the unique ability to model the compression set of elastomers to predict seal lifetime using finite element analysis (FEA) for its semiconductor customers.

Gulcur notes: “This approach enables engineers to capture more accurate seal compression set data compared to industry standard simulation compression set tests, allowing for more accurate predictions about seal longevity. Our extensive ability to work with customers to develop custom seals for specific applications will also be highlighted.”

Finally, Trelleborg highlights its Turcon® Variseal® spring-energized seals for high vacuum and corrosive environments. These seals operate in extreme temperatures and have excellent wear and friction characteristics. Compatible with virtually all media and gases including fluorine at high temperatures, they are available in custom sizes and standard dimensions.

For more details about semiconductor manufacturing capabilities from Trelleborg Sealing Solutions, visit: trelleborg.com/en/seals/your-industry/semiconductor

For further details about SEMICON West, go to: semiconwest.org/