Kontron, a leading global provider of IoT technology, the company is expanding its expertise in plastics processing through its Electronics² service brand. Through extensive investments in state-of-the-art injection molding machines at its Leipzig site, the company is strengthening its vertical integration capabilities and expanding its services for demanding applications in industrial electronics, medical technology, energy technology, and automotive technology.

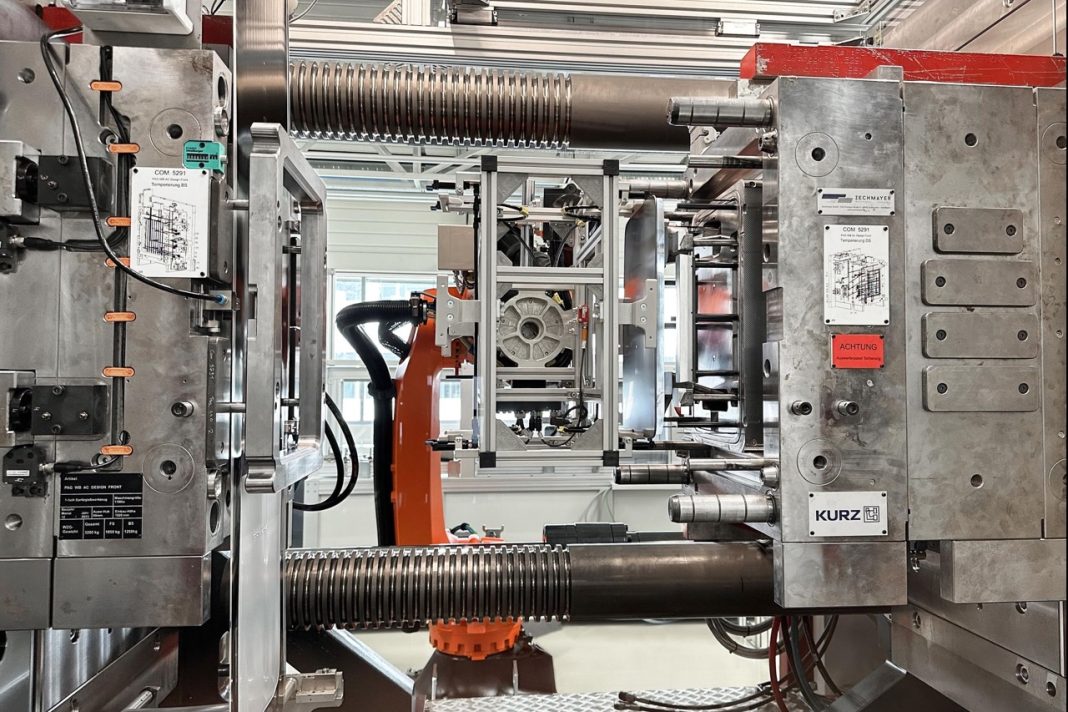

By expanding its production capacities and using highly automated injection molding at its Leipzig site, Kontron eSystems is strengthening its position within the Electronics² network as a high-performance plastics processing partner. A key component of this expansion is the automated in-mold decoration (IMD) process, which produces high-quality, visually appealing parts with an excellent surface finish. For the first time, all plastic parts can be manufactured directly at the Leipzig site. This increased vertical manufacturing capacity significantly reduces dependence on external suppliers and strengthens supply chain resilience within the Kontron Group.

Significant added value for customers is provided by the complete integration of plastics processing and electronics manufacturing at a single location. Seamless integration of all development, production, and quality assurance processes enables short response times and customized solutions. This allows us to produce cutting-edge components of the highest quality under one roof, especially for applications in electromobility.

The entire production infrastructure is designed to meet the highest quality standards and offers short production times and maximum design and variant flexibility. Thanks to fully automated handling and packaging processes, clean room – compliant visible component manufacturing, and a central material supply, a wide variety of customer requirements can be met. Modern production cells, automated component removal, camera-assisted quality assurance, and a fully integrated packaging system ensure smooth operations. A driverless transport system at the site complements these features, ensuring a continuous and economical high-performance process.

Electronics² unites the manufacturing and development expertise of Kontron, KATEK, and beflex electronic. Within this network, the Leipzig location of Kontron eSystems acts as a center of excellence for developing and manufacturing complex plastic visual and functional components for a wide range of industries, from simple components to highly complex ones with particularly demanding visual requirements. Through its Electronics² service brand, Kontron takes an integrative approach to developing, manufacturing, and integrating plastic and electronic assemblies. The brand stands for reliable processes, maximum flexibility, and custom solutions, even for complex, high-quality applications.

Further Information:

For more information, please visit: kontron.com/en/products-solutions/electronics2